Supplier development has become a cornerstone of modern business strategy, offering companies the ability to enhance supply chain efficiency, foster innovation, and create lasting partnerships. As global markets evolve at an unprecedented pace, businesses are increasingly recognizing the value of investing in their supplier relationships. By focusing on supplier development, organizations can achieve cost savings, improve product quality, and drive long-term growth. In this article, we will explore the critical role supplier development plays in shaping successful businesses and provide actionable insights to help companies implement effective strategies.

Today's competitive landscape demands more than just transactional relationships between businesses and their suppliers. The emphasis on collaboration, shared goals, and mutual growth has transformed supplier development into a strategic priority. Companies that prioritize supplier development are better equipped to navigate challenges such as supply chain disruptions, market volatility, and evolving customer demands. By investing in supplier capabilities, businesses can unlock new opportunities for innovation and efficiency.

As we delve deeper into this topic, you will discover the key principles of supplier development, its impact on business performance, and how organizations can implement best practices to achieve success. Whether you are a small business owner, a procurement professional, or a supply chain manager, this article will provide valuable insights and actionable advice to help you harness the full potential of supplier development.

Read also:Miaz1234 Vs Girthmaster A Comprehensive Analysis And Comparison

What Is Supplier Development and Why Is It Important?

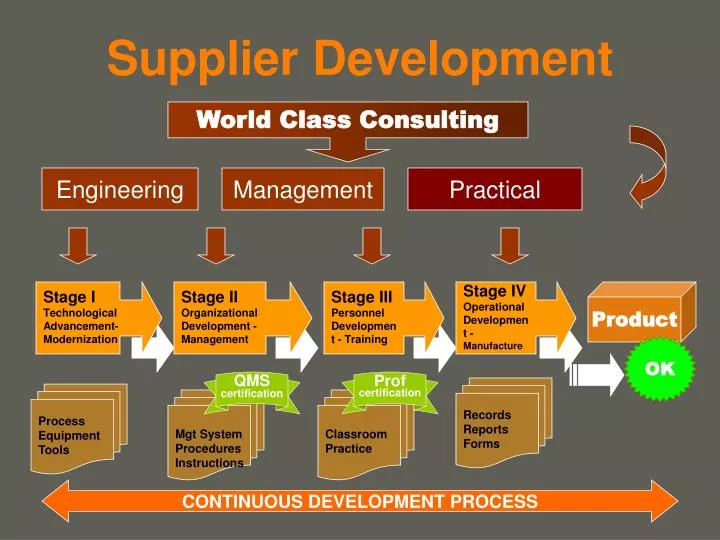

Supplier development refers to the process of enhancing the capabilities of suppliers to improve their performance, reliability, and innovation. This strategic approach involves working closely with suppliers to identify areas for improvement, provide training and resources, and foster collaboration. The importance of supplier development lies in its ability to strengthen the supply chain, reduce costs, and drive innovation, ultimately leading to improved business performance.

One of the primary reasons supplier development is critical is its role in mitigating risks associated with supply chain disruptions. By investing in supplier capabilities, businesses can ensure continuity of supply and adapt to changing market conditions. Additionally, supplier development enables companies to leverage the expertise and innovation of their suppliers, leading to the development of new products and processes that can give them a competitive edge.

How Does Supplier Development Impact Business Performance?

The impact of supplier development on business performance is significant and multifaceted. Companies that invest in supplier development often experience improved product quality, reduced lead times, and increased innovation. These benefits translate into cost savings, enhanced customer satisfaction, and improved market position. Furthermore, supplier development fosters stronger relationships between businesses and their suppliers, creating a foundation for long-term collaboration and mutual growth.

In addition to these tangible benefits, supplier development also contributes to the overall sustainability of the supply chain. By working with suppliers to implement environmentally friendly practices and improve resource efficiency, businesses can reduce their carbon footprint and contribute to a more sustainable future. This aligns with growing consumer demand for environmentally responsible products and practices.

Can Supplier Development Help Reduce Costs?

A common question among businesses is whether supplier development can help reduce costs. The answer is a resounding yes. By investing in supplier development, companies can achieve cost savings through improved efficiency, reduced waste, and enhanced productivity. For example, a manufacturer may work with its suppliers to optimize production processes, resulting in lower costs and faster delivery times. Additionally, supplier development can lead to the identification of alternative materials or components that are more cost-effective without compromising quality.

What Are the Key Principles of Successful Supplier Development?

To implement a successful supplier development program, businesses must adhere to several key principles. These include clear communication, collaboration, and a focus on continuous improvement. Establishing clear expectations and performance metrics is essential to ensure alignment between businesses and their suppliers. Regular communication and feedback loops help identify areas for improvement and track progress over time. Furthermore, fostering a culture of collaboration and mutual respect is crucial to building strong, lasting relationships.

Read also:Sza Height In Cm Discovering The Truth Behind The Singers Stature

Why Should Companies Invest in Supplier Development?

Investing in supplier development is not just a nice-to-have; it is a necessity for modern businesses looking to thrive in a competitive market. By prioritizing supplier development, companies can achieve numerous benefits, including improved product quality, increased innovation, and cost savings. Additionally, supplier development helps mitigate risks associated with supply chain disruptions, ensuring continuity of supply and adaptability to changing market conditions.

To illustrate the value of supplier development, consider the example of a technology company that partners with its suppliers to co-develop new products. By investing in supplier capabilities, the company can accelerate the innovation process, bringing cutting-edge products to market faster and more efficiently. This not only enhances the company's competitive position but also strengthens its relationship with suppliers, creating a win-win scenario for both parties.

How Can Businesses Implement Effective Supplier Development Strategies?

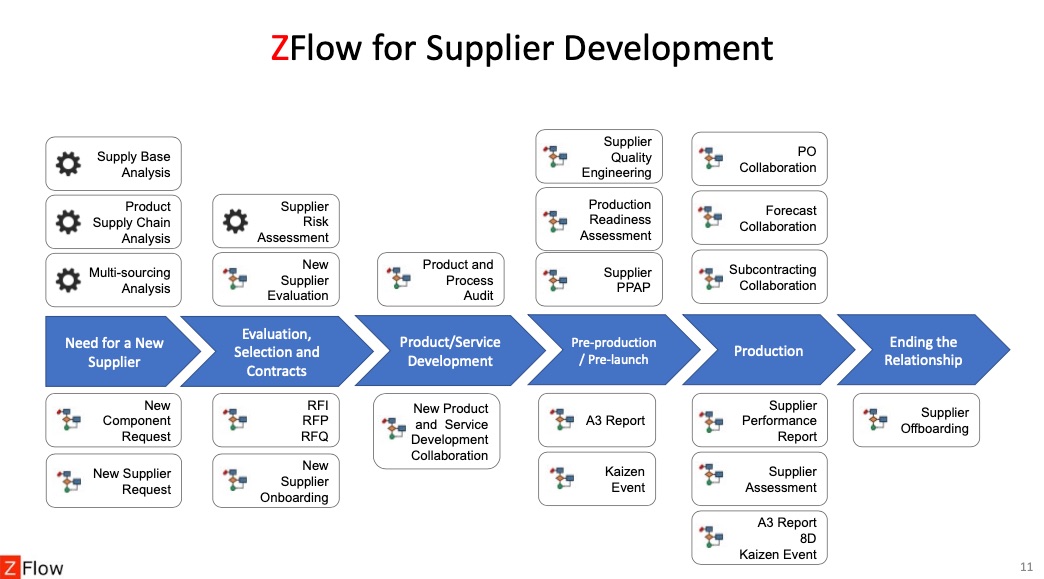

Implementing effective supplier development strategies requires a structured approach that aligns with the organization's overall business objectives. Businesses should begin by identifying key suppliers and assessing their current capabilities. This involves conducting thorough evaluations to determine areas for improvement and setting clear goals for development. Once these foundational steps are complete, businesses can develop tailored strategies to address specific needs and challenges.

Some effective strategies for supplier development include providing training and resources, sharing best practices, and fostering collaboration through regular communication and feedback. Additionally, businesses can incentivize suppliers to adopt new technologies or processes that enhance efficiency and innovation. By taking a proactive and strategic approach to supplier development, companies can achieve significant improvements in supply chain performance.

Is Supplier Development Only for Large Companies?

Many small and medium-sized enterprises (SMEs) may wonder if supplier development is only relevant for large companies. The truth is that supplier development is equally important for SMEs, as it can help them compete more effectively in the marketplace. By investing in supplier development, SMEs can improve product quality, reduce costs, and enhance innovation, enabling them to better meet customer demands and grow their businesses.

For SMEs, the key to successful supplier development lies in focusing on high-impact areas and leveraging partnerships with other organizations. Collaborating with industry associations, government agencies, or larger companies can provide SMEs with access to resources and expertise that may otherwise be out of reach. By taking advantage of these opportunities, SMEs can implement effective supplier development strategies that drive growth and success.

What Role Does Technology Play in Supplier Development?

Technology plays a crucial role in supplier development, enabling businesses to streamline processes, enhance communication, and track progress more effectively. Tools such as enterprise resource planning (ERP) systems, supplier relationship management (SRM) platforms, and collaborative platforms can help businesses manage supplier relationships more efficiently and make data-driven decisions.

For example, an SRM platform can facilitate communication between businesses and their suppliers, providing a centralized location for sharing information, tracking performance, and addressing issues. Additionally, advanced analytics and data visualization tools can help businesses identify trends and insights that inform supplier development strategies. By embracing technology, businesses can enhance the effectiveness of their supplier development efforts and achieve better outcomes.

What Are the Challenges of Supplier Development?

While supplier development offers numerous benefits, it is not without its challenges. One of the primary challenges is aligning supplier goals with those of the business. Suppliers may have different priorities, timelines, or capabilities, making it difficult to establish a cohesive strategy. Additionally, businesses may face resistance from suppliers who are reluctant to invest in development initiatives or share sensitive information.

To overcome these challenges, businesses must focus on building trust and fostering collaboration. This involves creating clear communication channels, setting realistic expectations, and providing incentives for suppliers to participate in development initiatives. By addressing these challenges proactively, businesses can create a foundation for successful supplier development.

How Can Businesses Measure the Success of Supplier Development?

Measuring the success of supplier development is essential to ensuring that initiatives are delivering the desired outcomes. Businesses should establish key performance indicators (KPIs) that align with their overall business objectives and supplier development goals. These KPIs may include metrics such as product quality, delivery times, cost savings, and innovation.

Regularly reviewing and analyzing performance data allows businesses to identify areas for improvement and adjust their strategies accordingly. Additionally, businesses should solicit feedback from suppliers to gain insights into their experiences and perspectives. By incorporating this feedback into their supplier development efforts, businesses can create more effective and impactful programs.

Can Supplier Development Be Applied Across Industries?

Supplier development is a versatile strategy that can be applied across a wide range of industries, from manufacturing and technology to healthcare and retail. The principles of supplier development remain consistent regardless of the industry, focusing on collaboration, continuous improvement, and shared goals. However, the specific strategies and tactics used may vary depending on the unique characteristics and challenges of each industry.

For example, a healthcare company may focus on supplier development initiatives that enhance patient safety and improve regulatory compliance, while a retail company may prioritize supplier development efforts that reduce costs and improve product availability. By tailoring supplier development strategies to the specific needs of their industry, businesses can achieve optimal results and drive success.

What Are the Future Trends in Supplier Development?

The future of supplier development is shaped by emerging trends such as digital transformation, sustainability, and globalization. As businesses continue to embrace technology, they will increasingly rely on digital tools and platforms to enhance supplier development efforts. Additionally, the growing emphasis on sustainability will drive businesses to focus on environmentally responsible practices and supply chain transparency. Finally, globalization will require businesses to develop strategies that address the complexities and challenges of international supply chains.

To stay ahead of these trends, businesses must remain adaptable and open to innovation. By continuously evaluating and refining their supplier development strategies, companies can position themselves for long-term success in an ever-changing market.

Table of Contents

- What Is Supplier Development and Why Is It Important?

- How Does Supplier Development Impact Business Performance?

- Can Supplier Development Help Reduce Costs?

- What Are the Key Principles of Successful Supplier Development?

- Why Should Companies Invest in Supplier Development?

- How Can Businesses Implement Effective Supplier Development Strategies?

- Is Supplier Development Only for Large Companies?

- What Role Does Technology Play in Supplier Development?

- What Are the Challenges of Supplier Development?

- How Can Businesses Measure the Success of Supplier Development?